Our Facilities

West Special Fasteners are specialist hot forgers of high nickel alloys and stainless steels.

Unique hot forging capability

In our 28000 SQ FT Factory in Dronfield (near Sheffield) we employ 66 full time employees.

Our standard size range for forged fasteners is 1/4″ to 2″ for imperial fasteners and M5 to M52 for metric fasteners. Our range of CNC and manual machined fasteners is from 3/16″ to 4″ Dia for imperial fasteners and M3 to M100 for metric fasteners.

Standard Lengths for forged fasteners are 10mm to 500mm long under the head of the fastener dependant on the diameter.

Proud British Engineering

To complement our hot forging facilities we have a wide variety of conventional lathes, automatic lathes, CNC lathes, hydraulic presses, thread rolling, drilling machines, milling machines, and VMC with 4th axis. This enables us to produce fasteners outside the standard range and length stated above.

Products can be identified with material grade, cast numbers and manufacturers initials by Multitronic Dot Marking or by conventional impact stamping when requested.

We can perform Positive Material Identification, PMI, in house using our XRF guns, and offer Fischer Ferrite Scope testing and Electrolytic weld cleaning.

Coating & tooling

PTFE, Xylan, Zinc and other coatings can be organized and we have vendors offering excellent world class facilities locally, to perform independently verified testing , Heat Treatment in API approved furnaces and high quality welding of exotic alloys.

Tooling for the mechanical presses is produced in-house. Chaser dies, taps, drills and other tools can all be reground, sharpened or modified in our factory.

OUR CAPABILITIES

Our services & facilities

Hot Forging

Our in-house hot forging capabilities are engineered to deliver exceptional strength and reliability in critical applications. As a leading hot forging manufacturer in the UK, we provide bespoke solutions in exotic materials, supporting industries where durability, corrosion resistance, and compliance are non-negotiable.

We specialise in custom forging in materials such as nickel alloys and stainless steels, delivering fasteners that withstand extreme conditions, from deep-sea pressure to chemical exposure. Our engineers work closely with clients to produce high-performance parts tailored to specific technical and environmental requirements.

We are one of only a handful of UK companies with dedicated hot press forging facilities. This capability enables us to shape high-integrity fasteners to customer-specific geometries while preserving the mechanical properties of the base material, essential for sectors such as renewables, marine, defence, and chemical processing.

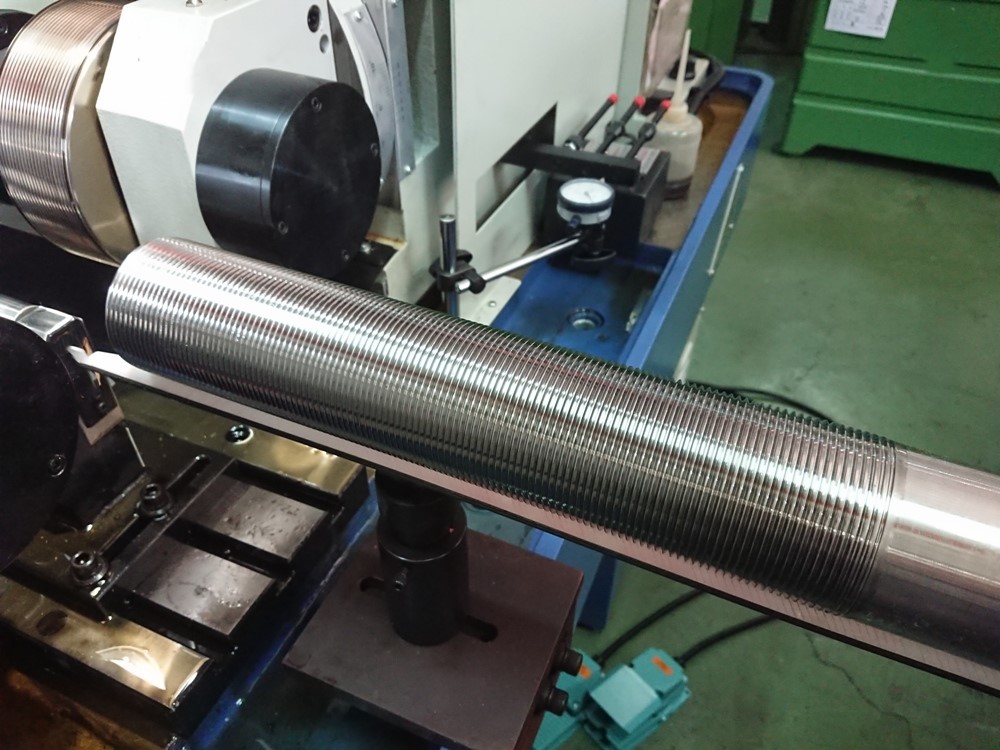

Thread Rolling

We provide expert thread rolling services for clients requiring durable, high-performance fasteners.

As one of the UK’s specialist thread rolling companies, we offer precision and reliability where it matters most, in offshore, defence, chemical, and renewable energy sectors.

Thread rolling is a cold-forming process that displaces material to form threads rather than cutting them. This method enhances tensile strength, surface finish, and fatigue resistance, making it ideal for safety-critical environments.

Compared to cut threads, rolled threads are smoother, stronger, and more consistent, perfect for fasteners exposed to high stress, vibration, or corrosive environments.

Material compatibility: Nickel alloys, stainless steel, Duplex/Super Duplex, and Titanium.

External thread rolling up to M72.

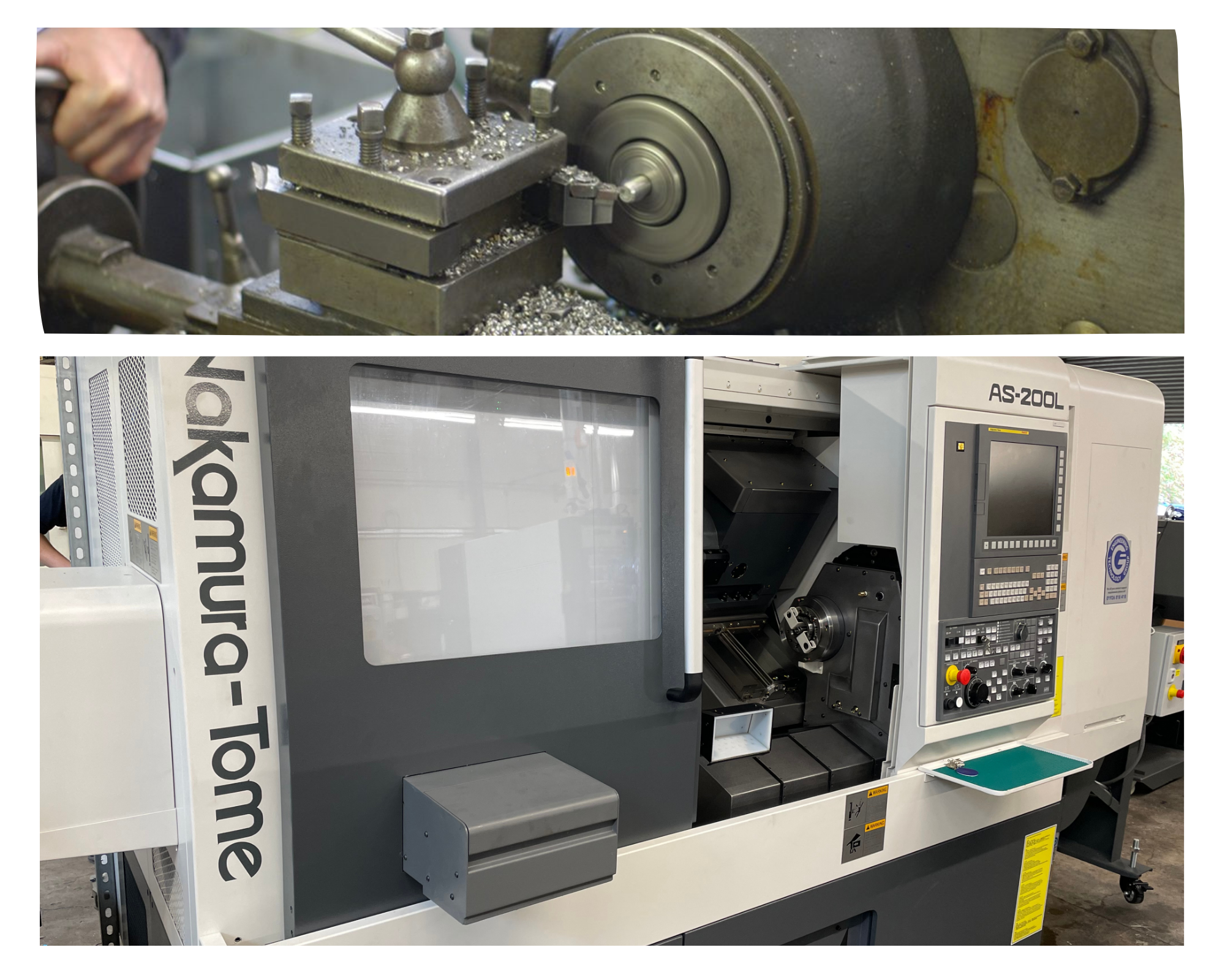

Turned Parts

We combine traditional machining expertise with the latest CNC technology to produce precision fasteners in stainless steels and high-performance alloys. Our workshop includes both manual lathes and modern CNC and vertical machining centres (VMCs), allowing us to deliver quality, flexibility, and accuracy across every order.

Our manual lathes are ideal for small batches, prototypes, and specialist components. Skilled machinists use them to carry out fine adjustments, intricate detailing, and one-off modifications that demand a craftsman’s touch. This ensures complete control over dimensions and surface finishes, particularly on bespoke or urgent jobs.

Our CNC lathes and VMCs bring speed, repeatability, and precision to larger production runs and complex geometries. Multi-axis and 4th-axis capabilities allow multiple features to be machined in a single setup, maintaining concentricity, and reducing lead times. These advanced systems enable us to achieve tight tolerances, exceptional surface finishes, and consistent quality across high-performance fasteners.

By combining traditional skill with modern technology, West Special Fasteners delivers a versatile machining capability, from a single prototype to full production, ensuring each component meets the exacting standards of industries where performance and reliability are essential.

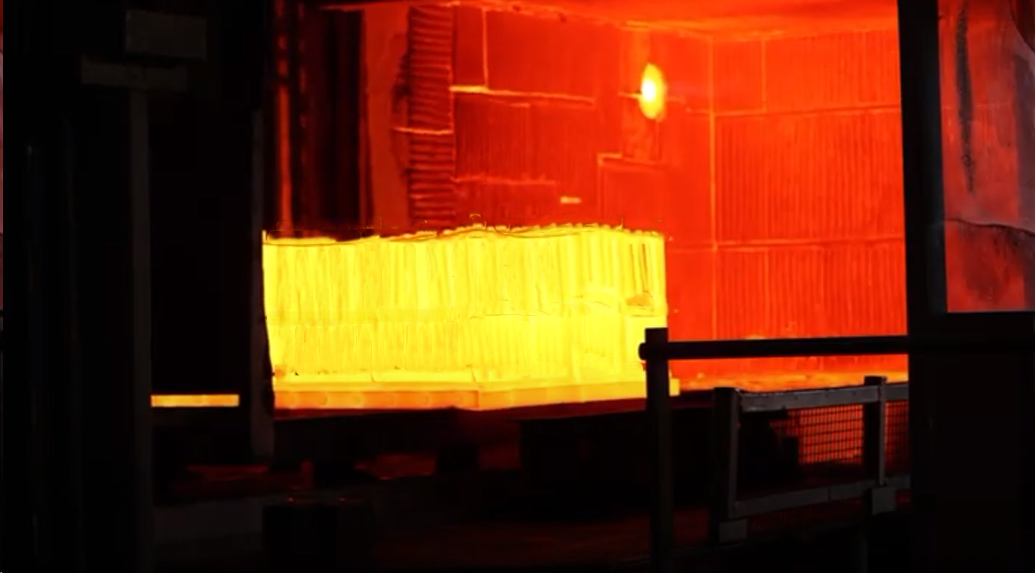

Heat Treatment

We provide heat treatment services to enhance the mechanical properties of fasteners manufactured from stainless steel, nickel alloys and other exotic materials. Using API-approved furnaces, the process can include treatments such as hardening & tempering, solution annealing, stress relieving and other customer-specified heat cycles. These treatments improve strength, fatigue performance, ductility, hardness and corrosion resistance, essential in demanding environments like marine, offshore, chemical, power generation and defence. With full material traceability and stringent testing standards, every treated component is certified to meet the highest quality and regulatory specifications.

Testing

We offer comprehensive in-house testing services to ensure the performance, reliability, and full traceability of our fasteners. Our in-house capabilities include hardness testing, and non-destructive testing (NDT), all performed to verify that every component meets stringent quality requirements.

As part of our advanced testing process, we utilise an XRF (X-Ray Fluorescence) gun to carry out positive material identification (PMI). This non-destructive technique allows us to accurately analyse the elemental composition of materials, confirming that each batch conforms precisely to the specified alloy grade. The XRF testing capability enhances our quality assurance by preventing material mix-ups, ensuring full compliance with customer and industry standards, and providing documented traceability.

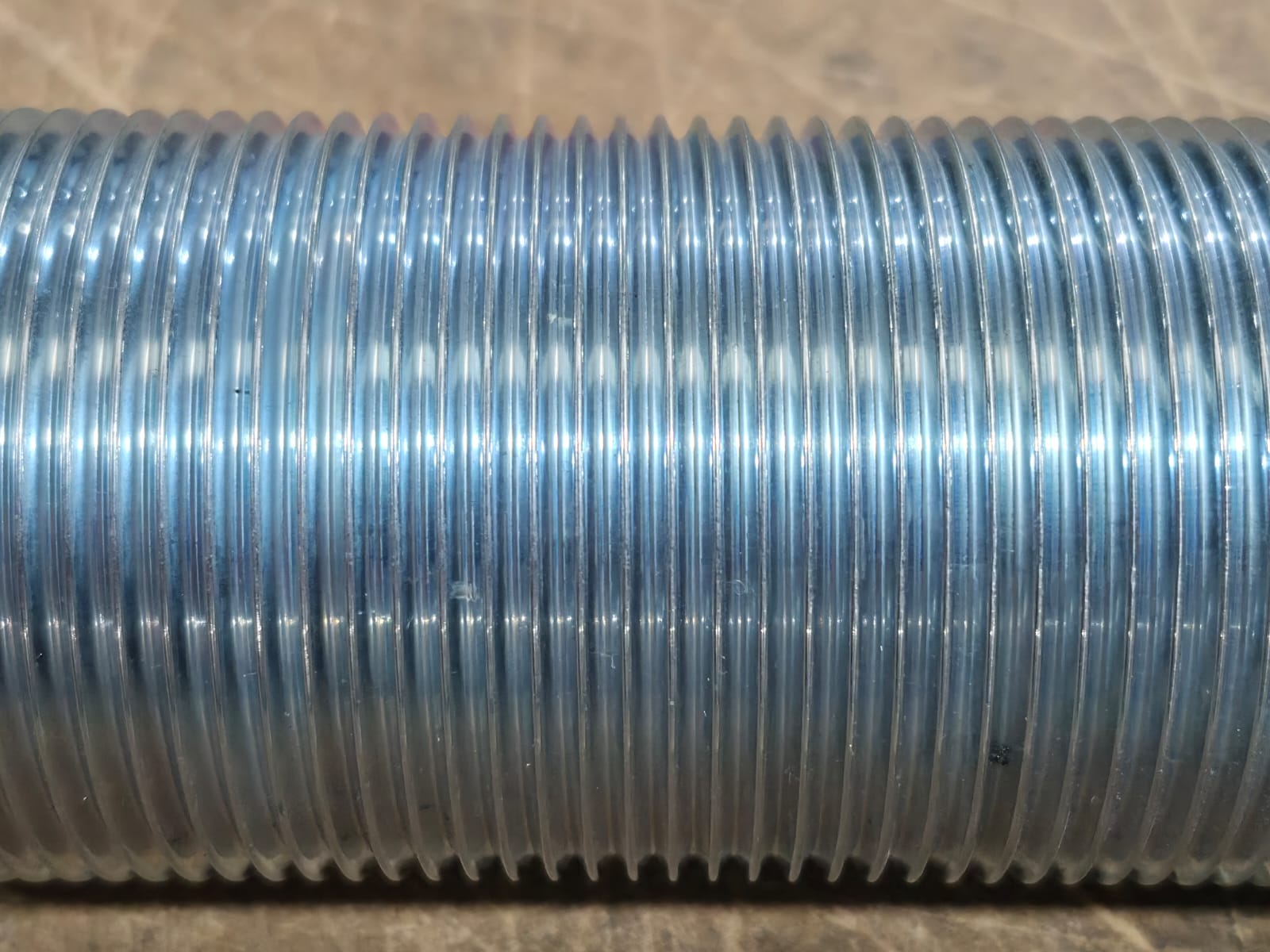

Plating

West Special Fasteners provides specialist plating services to enhance corrosion resistance, wear protection, and surface conductivity of fasteners. We work with a range of finishes, tailored to meet the requirements of demanding environments in marine, defence, and chemical sectors.

Corrosion resistance

Enhanced durability

Ensuring Durability in Harsh Environments

West Special Fasteners supplied high-performance Super Austenitic Stainless Steel fasteners, essential for the durability and corrosion resistance of the roofs in Center Parcs’ subtropical swimming pools across the UK.

CONTACT US

Speak to an expert

Whether you have a question, want to explore collaboration possibilities, or require expert advice, we are here to assist you.

Phone

Location

Callywhite Ln, Dronfield, S18 2XR

///blues.trains.soup