Precision Fasteners For Offshore & Marine

We supply fully traceable, high-integrity fasteners engineered for offshore platforms, ships, and coastal structures. Built to withstand saltwater, corrosion, and extreme conditions.

Trusted by offshore, marine, and subsea industries worldwide

At West Special Fasteners, we understand the challenges unique to offshore and marine environments. From relentless salt spray and wave impact to high pressures and demanding safety standards, your projects need fasteners that deliver uncompromising strength, corrosion resistance, and total reliability.

Our custom-manufactured fasteners are trusted by clients across oil & gas platforms, wind farms, shipbuilding, marine engineering, and coastal infrastructure. Whether it’s holding together critical topside assemblies or securing vital subsea structures, we provide solutions that perform where failure simply isn’t an option.

ISO 9001-certified processes

Our rigorous quality management system ensures that everything we produce meets the highest standards of quality and consistency.

UK and EU-sourced materials

We source our materials locally to guarantee safety, compliance, reliability, and sustainability.

Exotic alloy expertise

We specialise in materials designed to withstand the most challenging environments, such as seawater corrosion, chemical applications and extreme pressures.

Full traceability

Our manufacturing processes include comprehensive documentation, ensuring every component is traceable from raw material to finished product.

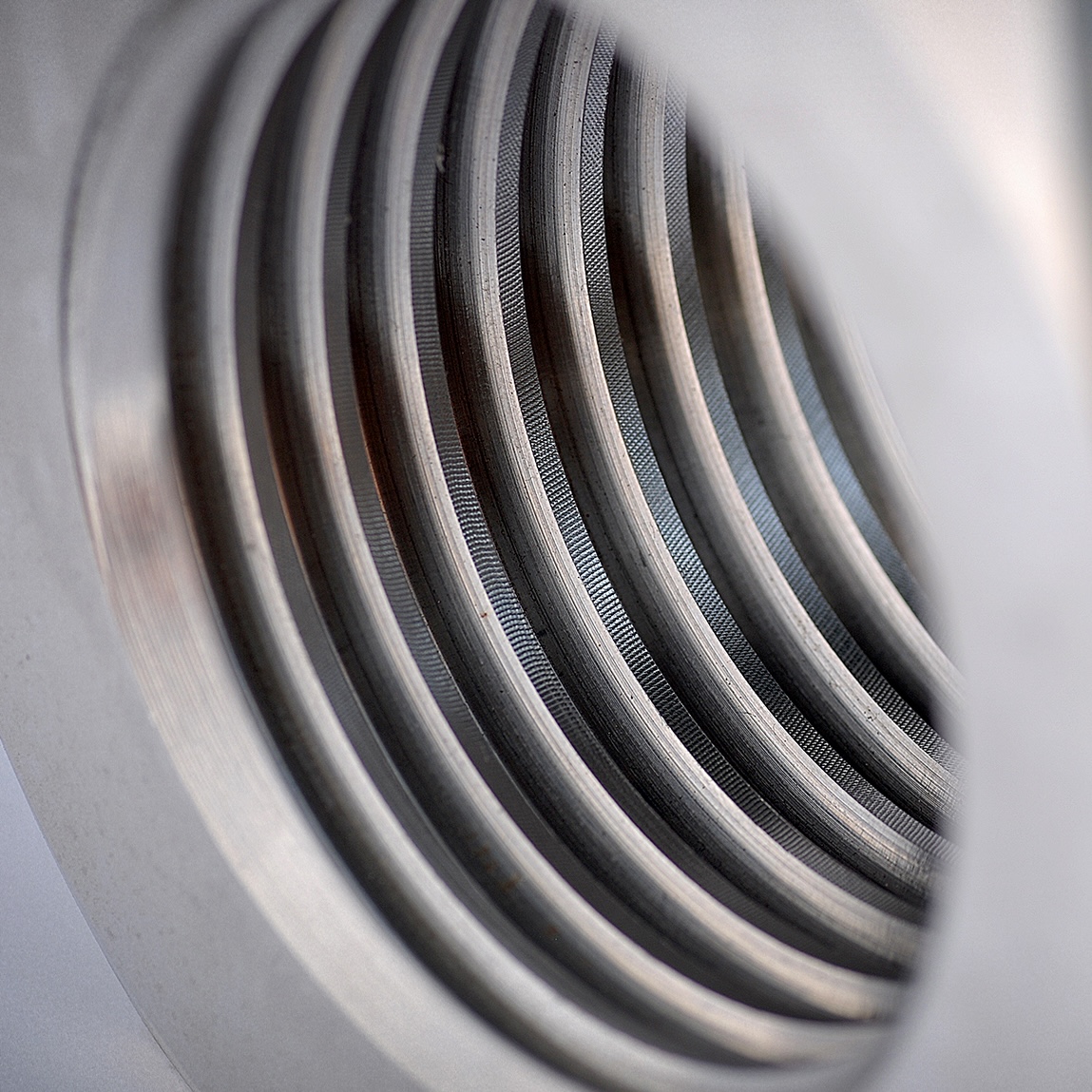

Bespoke fasteners for the harshest environments on earth

Marine and offshore projects expose components to some of the most aggressive conditions found anywhere. We specialise in supplying fasteners designed to survive:

-

Salt-laden atmospheres on offshore platforms and coastal installations.

-

Immersion in seawater, from subsea structures to ship hull fittings.

-

Dynamic stresses and vibration common on vessels, rigs, and wind turbines.

-

Temperature and pressure extremes in offshore oil & gas processing.

Typical applications include:

-

Offshore drilling rigs and production platforms

-

Subsea manifolds, risers, and wellheads

-

Wind turbines and associated offshore power structures

-

Ships, commercial vessels, and naval applications

-

Coastal and port infrastructure, jetties, and breakwaters

Corrosion-resistant alloys and protective finishes

We understand that corrosion is the single largest threat to offshore and marine assets. That’s why we manufacture fasteners from a wide selection of specialist materials and offer coatings tailored to your environment:

-

Duplex and super duplex stainless steels for excellent resistance to chloride-induced corrosion and stress cracking.

-

Nickel alloys such as Inconel and Monel, ideal for highly corrosive subsea and chemical service.

-

Hastelloy and exotic alloys where extreme resistance to both heat and chemical attack is critical.

-

Protective finishes, PTFE, and other specialist coatings, to prolong service life even further.

Our technical team works closely with design engineers and planners to recommend the optimal material and finish, ensuring fasteners match both functional requirements and long-term maintenance goals.

Your trusted partner for complex projects

In the offshore and marine sectors, delays can mean vast costs and operational headaches. That’s why we are proud to maintain a 99% on-time delivery rate, with typical lead times of around four weeks for a complete service, even on complex custom orders.

Our production planning is built around your critical path schedules, ensuring you receive the right components exactly when you need them, helping to keep costly installations, repairs, and shutdowns firmly on track.

Non-standard fasteners

Titanium Grade 5

From Dronfield to the Depths

West Special Fasteners supplied Titanium Grade 5 fasteners critical to the Triton 36000/2 submarine’s historic descent to the deepest part of the Mariana Trench.

CONTACT US

Speak to an expert

Whether you have a question, want to explore collaboration possibilities, or require expert advice, we are here to assist you.

Phone

Location

Callywhite Ln, Dronfield, S18 2XR

///blues.trains.soup