Fastener Solutions For Nuclear Projects

We manufacture fully traceable, high-integrity fasteners for nuclear power and scientific applications, engineered to meet the strictest safety and performance standards.

Supporting critical nuclear projects with expertise and reliability

At West Special Fasteners, we understand the unique demands of the nuclear sector and scientific engineering projects. From stringent quality standards to the need for absolute traceability, your operations rely on components that meet uncompromising specifications. That’s why we partner with power generation companies, scientific institutions, and contractors around the world to supply precision-manufactured fasteners tailored to these critical environments.

Whether for nuclear power plants, research reactors, or advanced scientific installations, our bespoke fastener solutions deliver the reliability and compliance that your projects demand. With decades of experience and a robust quality management system, we ensure every component is engineered to perform flawlessly, even in the most challenging conditions.

ISO 9001-certified processes

Our rigorous quality management system ensures that everything we produce meets the highest standards of quality and consistency.

UK and EU-sourced materials

We source our materials locally to guarantee safety, compliance, reliability, and sustainability.

Exotic alloy expertise

We specialise in materials designed to withstand the most challenging environments, such as seawater corrosion, chemical applications and extreme pressures.

Full traceability

Our manufacturing processes include comprehensive documentation, ensuring every component is traceable from raw material to finished product.

Tailored fasteners for nuclear applications

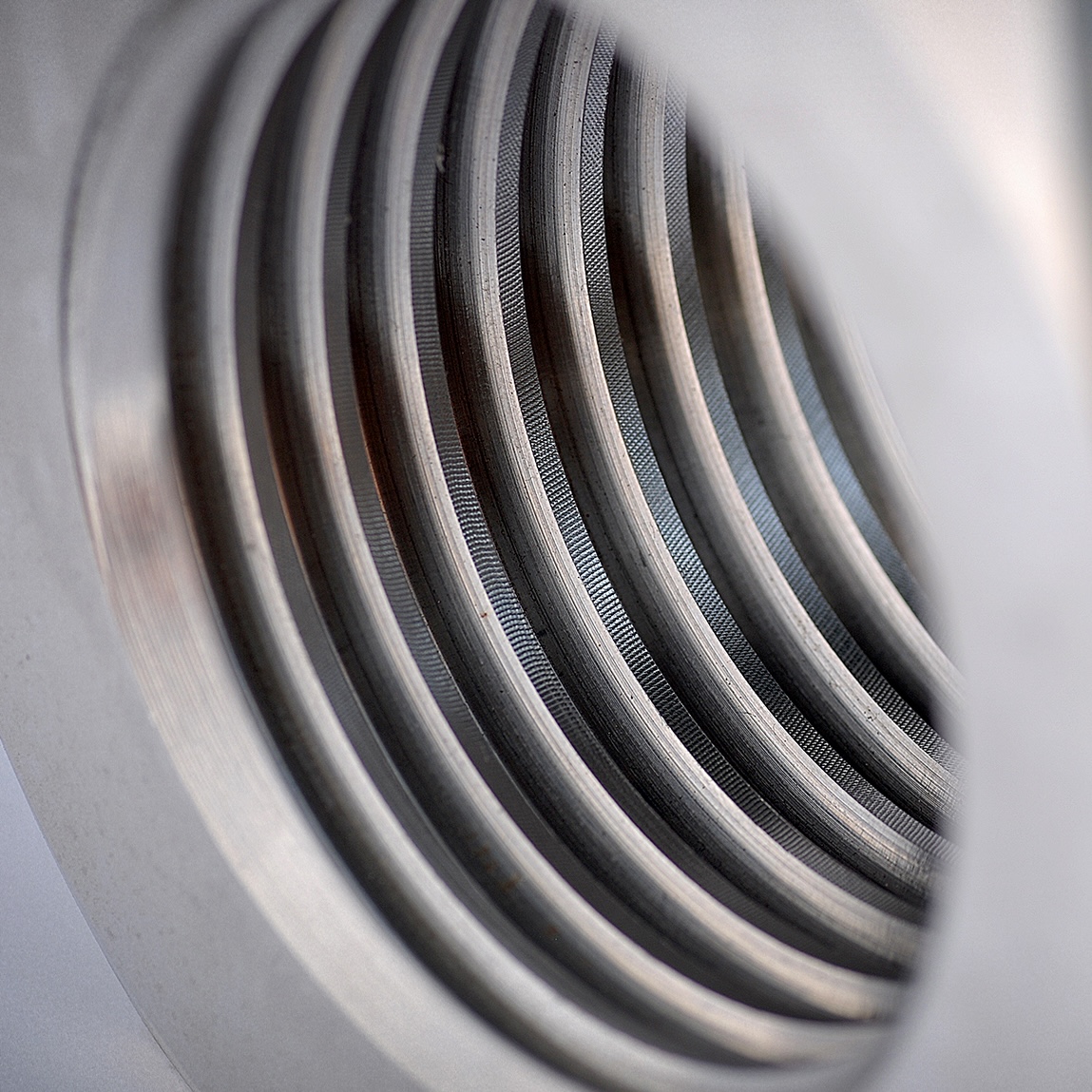

The nuclear industry demands a level of precision and assurance that few manufacturers can achieve. At West Special Fasteners, we specialise in custom fasteners crafted from high-performance alloys, designed to withstand radiation, extreme temperatures, and corrosive environments.

Our hot forging capabilities — one of only a handful in the UK — allow us to produce fasteners with exceptional structural integrity, while our comprehensive inspection processes guarantee each part meets rigorous specifications. From bolts and studs to nuts and special machined components, we manufacture to your exact drawings and technical requirements.

Our fasteners are used in:

-

Nuclear power plants and reactor assemblies

-

Steam turbines and heat exchangers

-

Fuel handling systems

-

Pressure vessels and containment

-

Experimental reactors and laboratory setups

Engineered to withstand the harshest environments

Fasteners used in nuclear and scientific settings are often exposed to aggressive conditions, including high temperatures, pressure, radiation, and corrosive media. To meet these challenges, we offer components manufactured from a wide range of specialist alloys, including:

- Duplex and super duplex stainless steels for superior corrosion resistance

- Nickel alloys (e.g., Inconel, Monel) for extreme temperature and chemical environments

- Hastelloy and other exotic materials for highly corrosive processes

With each order, we work closely with your engineering teams to select the optimal material grade, design, and heat treatment, ensuring long-term performance and safety.

Your trusted partner for complex projects

At West Special Fasteners, we take pride in being more than just a manufacturer. Our team supports customers throughout the project lifecycle — from early design input and prototype production through to volume supply and ongoing technical assistance. This collaborative approach helps mitigate risk, shorten lead times, and keep critical projects on schedule.

Our typical lead time is around four weeks for a full service from order to delivery, backed by a 99% on-time delivery record that is critical for high-stakes industries like nuclear and scientific research. When downtime isn’t an option, you can trust us to deliver exactly what you need, when you need it.

Non-standard fasteners

Titanium Grade 5

From Dronfield to the Depths

West Special Fasteners supplied Titanium Grade 5 fasteners critical to the Triton 36000/2 submarine’s historic descent to the deepest part of the Mariana Trench.

CONTACT US

Speak to an expert

Whether you have a question, want to explore collaboration possibilities, or require expert advice, we are here to assist you.

Phone

Location

Callywhite Ln, Dronfield, S18 2XR

///blues.trains.soup