Fasteners for Chemical Processing & Industrial Plants

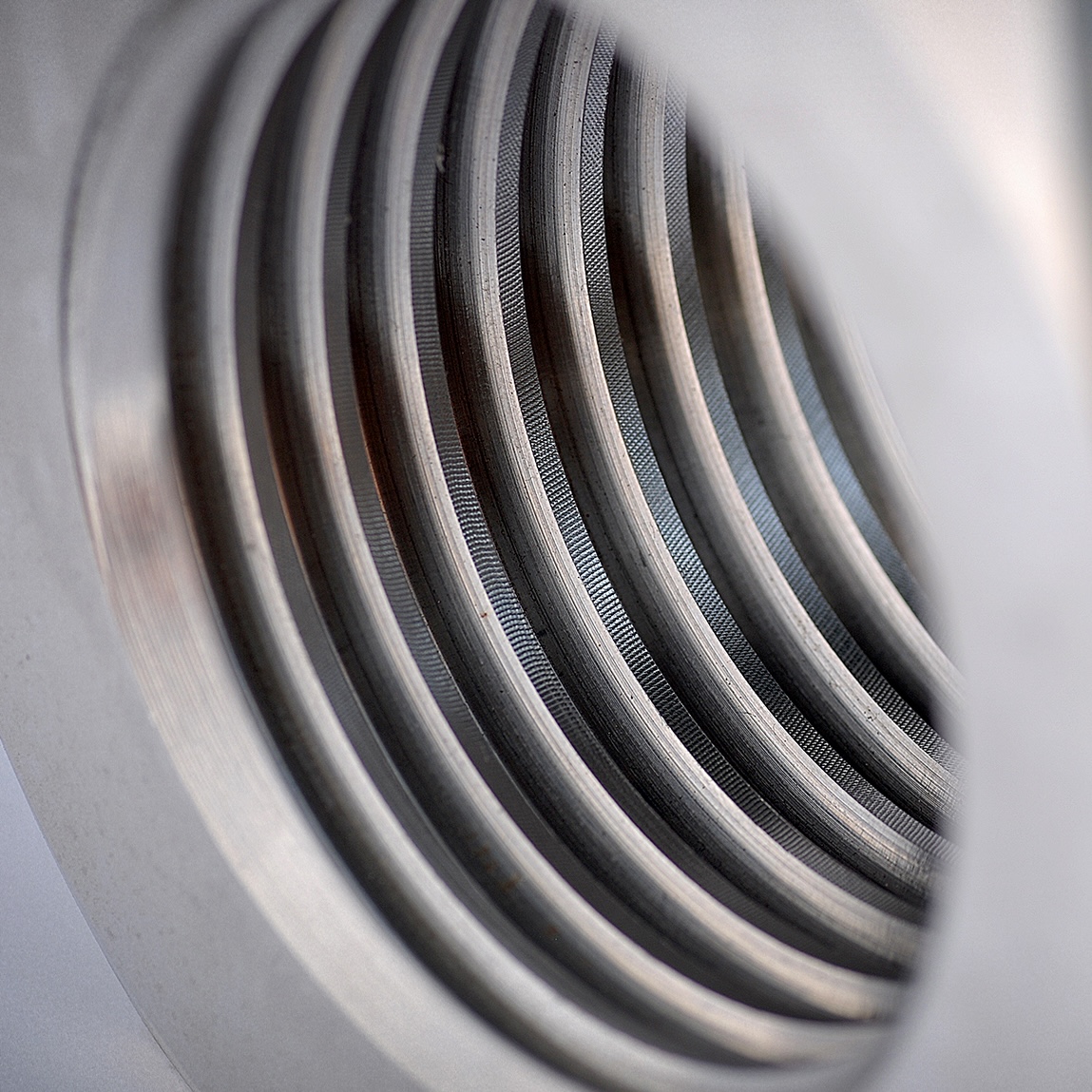

Precision-manufactured for corrosive and high-temperature environments, our fasteners deliver reliable long-term performance across chemical plants, refineries, and highly aggressive industrial applications.

Supporting chemical and process industries with engineered durability

Chemical environments demand components that can withstand extreme temperatures, corrosive media, pressure variations, and continuous operational cycles. Unplanned failures are costly, hazardous, and disruptive – which is why trusted, fully traceable fasteners are essential at every stage of your operation.

At West Special Fasteners, we manufacture high-integrity fasteners engineered specifically for chemical processing, petrochemical sites, refineries, and industrial plants worldwide. Our components meet strict mechanical and chemical requirements, ensuring operational safety, reliability and longevity in even the most aggressive conditions.

Whether you require specialised bolting for heat exchangers, pumps, pressure vessels or pipework systems, we manufacture to your exact drawings with full documentation and material traceability.

ISO 9001-certified processes

Our rigorous quality management system ensures that everything we produce meets the highest standards of quality and consistency.

UK and EU-sourced materials

We source our materials locally to guarantee safety, compliance, reliability, and sustainability.

Exotic alloy expertise

We specialise in materials designed to withstand the most challenging environments, such as seawater corrosion, chemical applications and extreme pressures.

Full traceability

Our manufacturing processes include comprehensive documentation, ensuring every component is traceable from raw material to finished product.

Tailored fasteners for chemical applications

Chemical processing operations place fasteners under continuous stress. From corrosive liquids and gases to thermal cycling and high-pressure systems. We produce custom components designed to withstand these conditions while maintaining structural integrity and long-term performance.

Our hot forging capability, offered by only a small number of UK manufacturers, enables exceptional strength and reliability for mission-critical components.

All fasteners undergo stringent inspection and certification to meet your project’s standards.

Our fasteners are used in:

Chemical plants and processing facilities

- Petrochemical refineries

- Heat exchangers, reactors and furnaces

- Pumps, valves and flanged assemblies

- Storage tanks and high-pressure pipework

- Acid-handling systems and corrosive fluid processes

- Waste treatment and filtration systems

Engineered to withstand corrosive and high-temperature conditions

Fasteners for chemical plants must deliver exceptional resistance to corrosion, pitting, stress cracking, and thermal shock. To achieve this, we supply components manufactured from specialist alloys selected for your exact process environment.

Material options include:

- Duplex and super duplex stainless steels for chloride-rich or acidic conditions

- Nickel alloys such as Inconel and Monel for high-temperature or chemically aggressive applications

- Hastelloy and similar alloys for highly corrosive or high-pressure chemical processes

- High-strength stainless steels for load-bearing or cyclic environments

We work collaboratively with your engineers and purchasing teams to ensure optimal material selection, heat treatment and design for each application.

Your trusted partner for demanding chemical environments

Chemical plants rely on predictable supply, accurate documentation and consistent manufacturing standards. With typical lead times of around four weeks and a 99% on-time delivery record, we provide the reliability needed to maintain uptime and prevent costly downtime.

From prototype development to repeat orders, our team supports you throughout the entire lifecycle of your project, ensuring each component performs safely and reliably under the harshest operational conditions.

Corrosion resistance

Enhanced durability

Ensuring Durability in Harsh Environments

West Special Fasteners supplied high-performance Super Austenitic Stainless Steel fasteners, essential for the durability and corrosion resistance of the roofs in Center Parcs’ subtropical swimming pools across the UK.

CONTACT US

Speak to an expert

Whether you have a question, want to explore collaboration possibilities, or require expert advice, we are here to assist you.

Phone

Location

Callywhite Ln, Dronfield, S18 2XR

///blues.trains.soup