Fastener Solutions for Critical Infrastructure

We manufacture fully traceable, high-integrity fasteners for bridges, tunnels, transport structures, and essential civil infrastructure. Engineered to deliver long-term reliability in demanding environments.

Supporting critical infrastructure with durability, precision, and trust

At West Special Fasteners, we understand the immense responsibility placed on infrastructure engineers. Bridges, tunnels, transport networks and structural frameworks must remain safe and stable for decades, often while exposed to heavy loads, harsh weather, seawater environments, and continuous vibration.

Your components cannot fail. That’s why we partner with infrastructure contractors, civil engineering firms, design consultancies, and government-led projects to supply precision-manufactured fasteners that meet stringent mechanical, safety, and documentation requirements.

From structural bolting systems to bespoke components for corrosion-prone coastal locations, our fasteners are engineered with the integrity, performance, and traceability that critical infrastructure demands.

ISO 9001-certified processes

Our rigorous quality management system ensures that everything we produce meets the highest standards of quality and consistency.

UK and EU-sourced materials

We source our materials locally to guarantee safety, compliance, reliability, and sustainability.

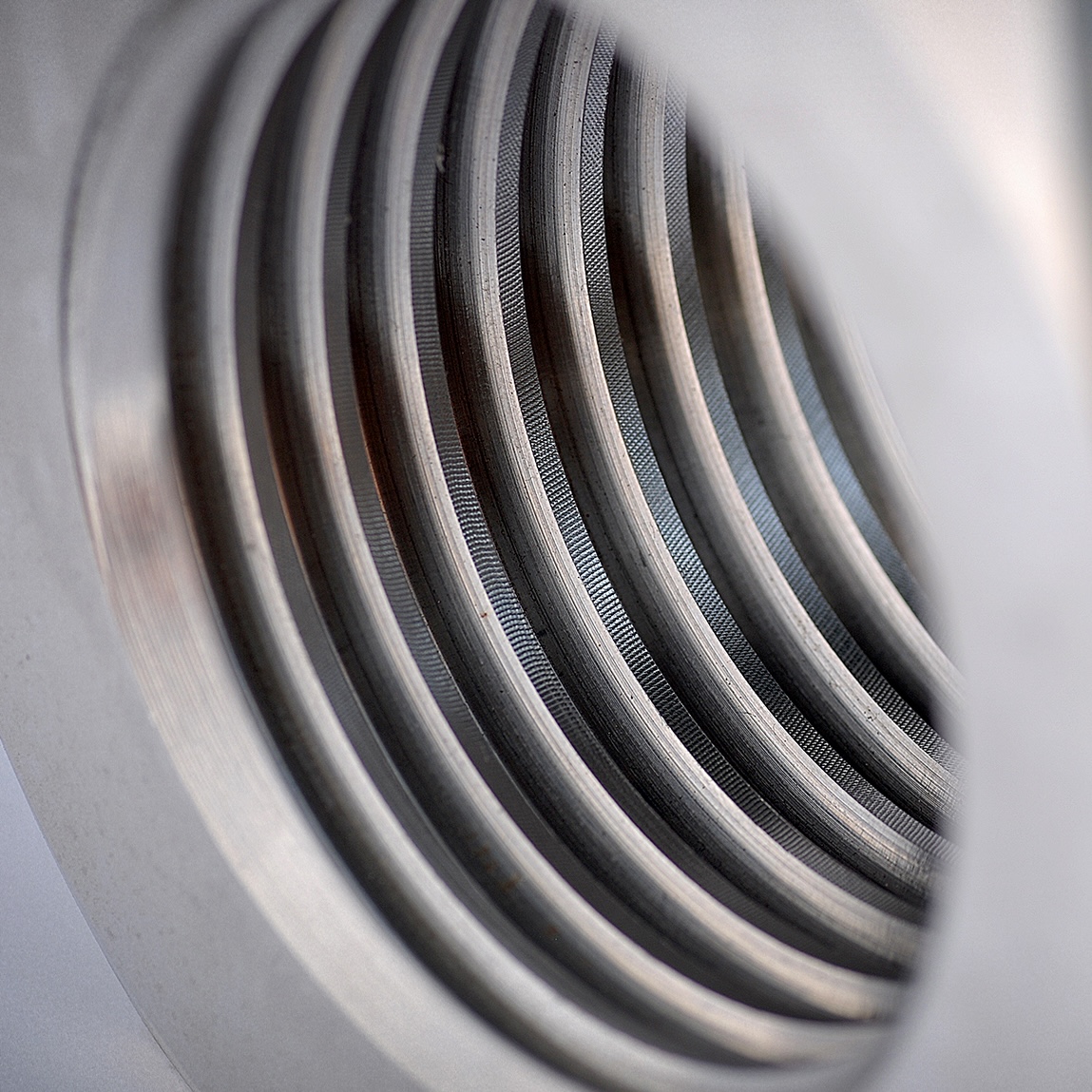

Exotic alloy expertise

We specialise in materials designed to withstand the most challenging environments, such as seawater corrosion, chemical applications and extreme pressures.

Full traceability

Our manufacturing processes include comprehensive documentation, ensuring every component is traceable from raw material to finished product.

Tailored fasteners for infrastructure applications

Civil and structural engineering projects depend on components that offer both mechanical strength and long-term environmental resistance. At West Special Fasteners, we specialise in manufacturing custom fasteners — from standard geometries to highly bespoke, project-specific components.

Our hot forging capabilities, available from only a small number of UK manufacturers, allow us to produce high-integrity fasteners with exceptional structural performance.

Combined with stringent inspection and documentation, we ensure every part meets your drawings, specifications, and compliance requirements.

Our fasteners are used in:

- Bridge construction and refurbishment

- Tunnel infrastructure and anchor systems

- Coastal and marine-adjacent structures

- Rail and road transport frameworks

- Load-bearing structural assemblies

- Water treatment, pumping and valve systems

- Seismic, vibration-prone, and fatigue-critical installations

Engineered for harsh and long-term environmental conditions

Infrastructure fasteners regularly endure extreme stresses, from heavy transport loads to saltwater corrosion and constant cyclic vibration. To maximise service life and performance, we supply components manufactured from a range of specialist alloys selected for the challenges of each environment.

Material options include:

- Duplex and super duplex stainless steels for corrosion-prone or coastal environments

- Nickel alloys for chemical exposure or high-temperature locations

- High-strength stainless steels for structural applications requiring fatigue resistance

- Specialist alloys for long-term performance in polluted, damp, or abrasive conditions

We collaborate directly with your engineers, planners, and project managers to determine the optimum material grade, heat treatment, and geometry to meet your performance criteria.

Your trusted partner for complex infrastructure builds

At West Special Fasteners, we pride ourselves on being a dependable manufacturing partner for large-scale and technically demanding infrastructure projects. We support your team from early design input and prototyping through to full production and repeat supply, ensuring accuracy, reliability, and clear communication throughout.

Our typical lead time is around four weeks, supported by our 99% on-time delivery record, which is vital for construction schedules where delays can disrupt entire project phases.

When deadlines matter and safety is paramount, you can rely on us to deliver exactly what you need, when you need it.

Corrosion resistance

Enhanced durability

Ensuring Durability in Harsh Environments

West Special Fasteners supplied high-performance Super Austenitic Stainless Steel fasteners, essential for the durability and corrosion resistance of the roofs in Center Parcs’ subtropical swimming pools across the UK.

CONTACT US

Speak to an expert

Whether you have a question, want to explore collaboration possibilities, or require expert advice, we are here to assist you.

Phone

Location

Callywhite Ln, Dronfield, S18 2XR

///blues.trains.soup