Fastener Solutions for Renewable Energy Projects

Offering durability in extreme environments, our high-integrity fasteners support wind, solar, tidal and other renewable energy projects worldwide.

Supporting the renewable sector with durability, precision, and long-term performance

Renewable energy installations face some of the harshest operating environments, from salt-rich offshore wind locations to vibration-heavy turbine assemblies and long-term UV or weather exposure in solar infrastructure. Your fasteners must deliver decades of safe, reliable performance, regardless of climate, corrosion or mechanical stress.

At West Special Fasteners, we manufacture fully traceable, precision-engineered fasteners designed specifically for renewable energy technologies. We partner with wind farm developers, tidal energy innovators, solar infrastructure contractors and engineering consultancies to supply components that meet stringent environmental and mechanical requirements.

Whether for offshore structures, turbine assemblies or critical mounting systems, our fasteners are engineered for resilience, safety and long-term operational stability.

ISO 9001-certified processes

Our rigorous quality management system ensures that everything we produce meets the highest standards of quality and consistency.

UK and EU-sourced materials

We source our materials locally to guarantee safety, compliance, reliability, and sustainability.

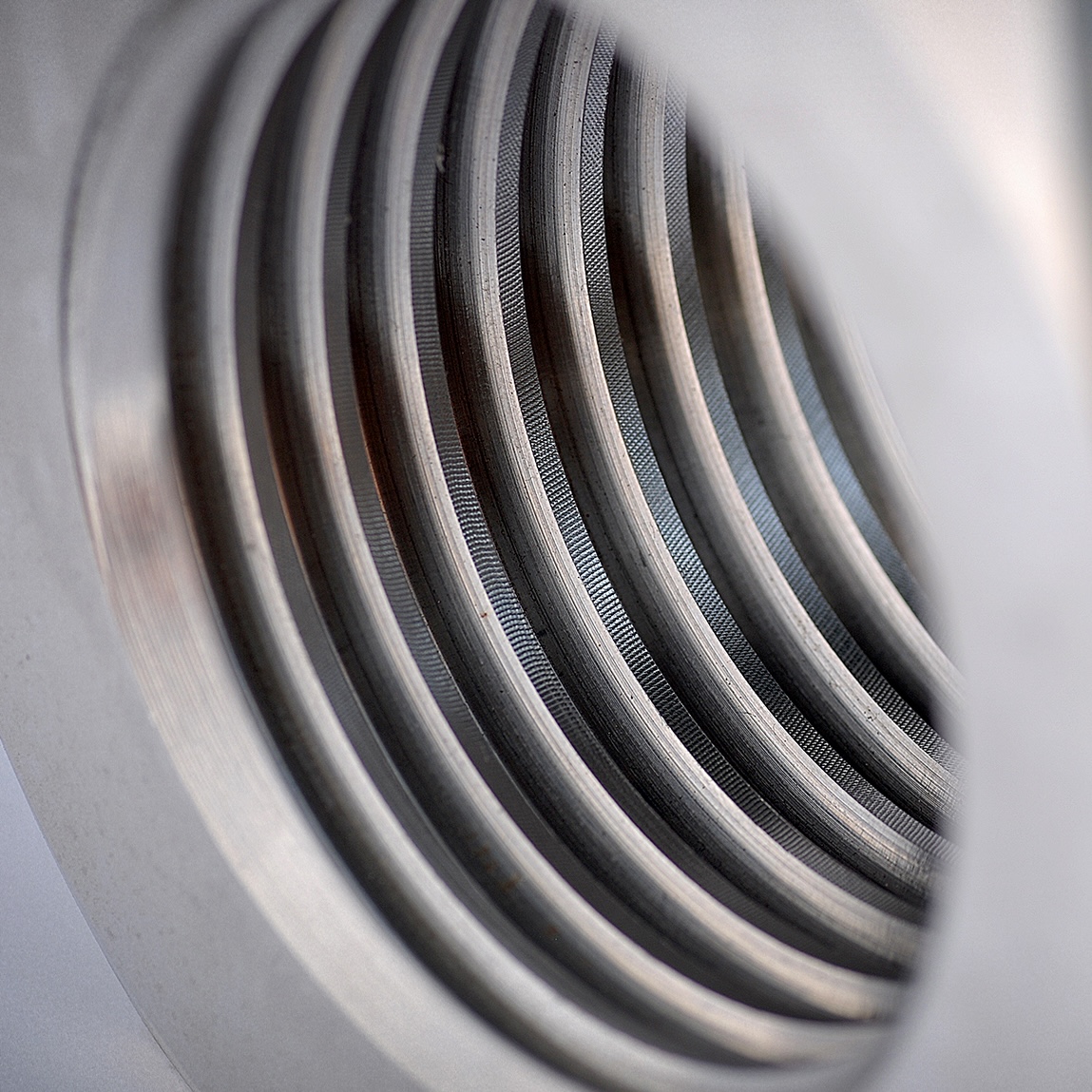

Exotic alloy expertise

We specialise in materials designed to withstand the most challenging environments, such as seawater corrosion, chemical applications and extreme pressures.

Full traceability

Our manufacturing processes include comprehensive documentation, ensuring every component is traceable from raw material to finished product.

Tailored fasteners for renewable energy applications

Renewable energy systems demand fasteners capable of resisting fatigue, vibration, corrosion and temperature fluctuations over extended lifetimes. Our bespoke manufacturing capabilities allow us to supply components precisely matched to each application’s environmental and mechanical demands.

With hot forging capabilities, we produce fasteners with exceptional structural integrity for high-stress and load-bearing applications.

Every component undergoes rigorous inspection and quality control to support the reliability required in global renewable installations.

Our fasteners are used in:

Offshore and onshore wind turbines

- Tidal and wave energy systems

- Solar mounting structures and tracking systems

- Subsea foundations and anchoring solutions

- Coastal infrastructure and marine-adjacent assets

- Hydrogen production and storage systems

- Renewable power transmission assemblies

Engineered for extreme and variable environmental conditions

Wind, tidal and solar projects expose fasteners to aggressive climates and continuous dynamic loads. To ensure long service life and optimal performance, we manufacture components using specialist alloys suited to marine, corrosive or high-load environments.

Material options include:

- Duplex and super duplex stainless steels for seawater and coastal corrosion resistance

- Nickel alloys for high-temperature, chemically harsh or fatigue-critical environments

- High-strength stainless steels for turbine and structural applications

- Specialist alloys for subsea, splash zone or high-cycling mechanical systems

Our team works directly with your engineers to determine the ideal material grade, heat treatment and design to meet lifetime and performance requirements.

Your trusted partner for renewable energy innovations

Renewable energy projects depend on reliable supply chains and consistent, high-quality manufacturing. With typical lead times of around four weeks and a 99% on-time delivery record, we support developers and contractors working to tight construction schedules and commissioning deadlines.

From prototypes and trial components to volume production for large-scale installations, we deliver precision-engineered fasteners that withstand the demanding conditions of renewable energy environments.

Non-standard fasteners

Titanium Grade 5

From Dronfield to the Depths

West Special Fasteners supplied Titanium Grade 5 fasteners critical to the Triton 36000/2 submarine’s historic descent to the deepest part of the Mariana Trench.

CONTACT US

Speak to an expert

Whether you have a question, want to explore collaboration possibilities, or require expert advice, we are here to assist you.

Phone

Location

Callywhite Ln, Dronfield, S18 2XR

///blues.trains.soup